Discover the project that’s repurposing ‘lost plastics’, improving inner-city recycling methods and finding opportunities for change during the pandemic.

8 min read

How easy is it to recycle plastics where you live? You can probably include plastic bottles in your curbside recycling collection, but what happens to other plastics like crisp packets, packaging or plastics used in commercial and industrial settings?

Plastic recycling rates are currently very low, especially in urban areas. A lot of plastic waste that could be recycled is often incorrectly identified or placed in the wrong recycling scheme. And it’s not always economically viable to recycle certain plastics.

Recovering lost plastics

We’re a partner in the PlastiCity project that aims to find these so-called ‘lost plastics’ and develop ways to increase recycling rates in urban areas from 20–30% to over 50%.

Our goal is to develop, demonstrate and implement new strategies to increase recycling, so that plastics become part of a circular economy rather than waste.

The project focuses on four case studies in partnering cities in the Interreg 2 Seas region: Ghent, Belgium; The Hague, Netherlands; Southend-on-Sea, United Kingdom and Douai in France. Urban areas in this region are some of the biggest producers of plastic waste in the European Union.

Watch this short animation to learn more about the project.

PlastiCity project, with subtitles

This animated video explains what the PlastiCity project is all about.

[Music]

Narrator: urban areas in the Interreg 2 seas region are one of the biggest producers of plastic waste in the European union.

In those urban areas you do not only find post-consumer waste, but also tons of commercial and industrial plastic waste.

These plastics often are perfectly eligible for recycling but they don't always find their way into the right recycling scheme.

Plasticity wants to find these lost plastics and develop technical solutions that will enhance the local circular economy by creating new value chains overall.

We want to develop replicable strategies and solutions to increase recycling rates in urban environments from 20 to 30 to over 50 percent by unlocking the use of lost plastics as secondary resources from the urban environment.

To do so, the main objectives of Plasticity are one: mapping and analyzing the quantities and qualities of industrial and commercial waste in urban areas.

Two: understanding the behaviour towards recycling of the various actors in the plastic value chain.

Three: developing innovative technical solutions for logistics and reprocessing of plastic waste.

Four: demonstrating replicable solutions for lumping plastic waste in four cities via a lab-scale recycling line in a mobile laboratory.

Five: inducing behaviour change by stakeholder surveys workshops and sensitization.

Six: creating business activity and employment in the circular economy by local urban plastic hubs.

The Plasticity approach can be extended beyond the case study regions and thereby help to further increase the plastic recycling rates in Europe and beyond.

In our mobile plastic recycling laboratory Plasticity will demonstrate how to find the best trade-off between quantity and quality.

The first step towards a new local plastic value chain is understanding the status quo of the plastic waste flows in the case study cities.

This starts with a thorough plastic waste characterization campaign that is paired with collection tests with the innovative new waste collection methods.

Afterwards lumping tests are conducted to find the optimal solutions regarding quantity versus quality for the local waste streams.

Furthermore, pre-treatment and reprocessing tests are conducted in the mobile recycling lab to optimize the quality of the possible recyclates.

Characterization of reprocessed material will allow us to estimate possible future applications that could be part of a new value chain.

Combined with research on the socio-economic behaviour towards recycling and new business models, we strive to create urban platforms for plastic recycling in our case cities.

Our plastic hubs will enable innovative ways to engage actors by creating a local network of partners from all over the plastic value chain.

This will create new business activity and employment in the circular economy.

Plasticity. We give lost plastics a destination.

Find out more on plastercityproject.eu and stay connected by our newsletter.

Finding innovative solutions to reuse plastic waste

We began the project by identifying which commercial and industrial sectors are producing waste that is not currently recycled, working in partnership with businesses, communities and governing bodies in the case study cities.

This involved collecting samples of plastic waste from shops and businesses and testing them in a purpose-built mobile lab. We categorised and tested the properties of the plastics to examine and demonstrate what commercially viable products can be made from them.

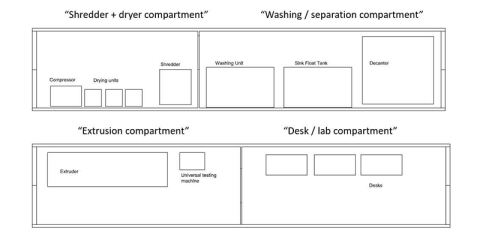

The mobile lab has two sections for the characterisation and processing of plastic waste

Categorising the plastics produced ‘lumping’ strategies, identifying what types of plastic can be bundled together for recycling companies. We can now develop cost effective business models to transform plastic waste into new products and materials.

The mobile lab is currently based in Ghent and will travel to the other case study cities in the project once COVID-19 restrictions allow. We’ll replicate the process of characterizing the properties and amount of plastic collected and then develop business cases, models and supply chains for eight new products to be made with the plastics in each city.

The lab equipment will eventually be available in a range of local hubs, which will bring people together to share ideas to develop new ideas and business plans for the circular economy. Plastic waste will be taken to the hubs to make products with local designers and small companies and promoted on ‘urban platforms’, putting together buyers and sellers in the cities.

Using the pandemic as an opportunity to test solutions

The COVID-19 pandemic inevitably impacted the project, with many engagement activities moving online. The virus also brought the issue of contamination into sharp focus. Some councils and cities stopped sorting plastic waste and incinerated the waste instead due to concerns of contamination on recycled plastics.

But we’ve turned the crisis into an opportunity. The use of PPE, commonly made from plastic-based materials, has risen by 300%, providing a chance to repurpose plastics recovered by the project.

Repurposing plastics for PPE

Using recycled plastic bottles, partners at The Hague City Council created face shields which were in high demand in the city. Ghent University repurposed its waste lab equipment, such as plastic pipettes, and developed EarBuddy — specially designed clips that secure the elastic fastenings of face masks at the back of the head. This reduces discomfort around the ears for healthcare professionals that wear masks for extended periods. 2,500 were produced and are being used in hospitals throughout Belgium.

The project has created 400 new jobs in developing new products from recycled plastics. Innovative approaches to recycling like this will lead to more employment opportunities in the circular economy.

Hague City Council created face shields using recycled plastic bottles for use as PPE in the COVID-19 pandemic

Plastic pipettes were recycled to create 'EarBuddy' — a clip that holds the elastic loops of a face mask to reduce irritation of the ears.

Consumer behaviour, recycling habits and plastic flows in the city

Understanding the consumer behaviour that will lead to enhanced recycling rates is an integral part of the project. At the current stage our partners in city councils are hosting online surveys and workshops in the region to build a clearer picture of consumer behaviour in relation to recycling plastics.

The surveys will be carried out with key actors in the plastics supply chain, such as logistics companies, product designers, waste and recycling companies, manufacturers and government representatives. The findings will allow us to identify barriers for recycling and develop models to encourage people to recycle more.

We’re also collaborating with our partners in The Hague, Ghent, Southend and Douai to better understand flows of commercial plastic waste, from its source to recycling sites. They are collecting technical data about the amount of plastic waste generated by businesses and how it is transported by waste logistic companies. We’ll then use this data to develop scenarios and simulations to minimize the distances travelled by plastic waste and therefore reduce carbon emissions.

A simulation has already been developed for France. We presented waste recyclers in Douai with an alternative strategy to collect plastic waste that would reduce transport time, costs and emissions by more than half.

Will the project help to improve recycling in other cities?

While PlastiCity is focussed on improving recycling rates in a specific region, the approach and methods can be replicated elsewhere.

The four case study cities differ in their economic landscapes, waste management schemes, cultural contexts, and local and regional policies. Insights into these differences and their impact on business models is necessary for replication and upscaling beyond the scope of the project.

For example, we’ve looked into transport modes in city centres in the Netherlands. Electric cargo bikes work well for collecting materials as they can access more areas in the city. While the bikes require charging and carry less material, they provide a solution for hard to reach areas that are inaccessible to large trucks.

This research demonstrates how innovative waste collection methods could facilitate recycling in densely populated towns and cities, where large lorries have difficulty manoeuvring and collecting waste. In time this could benefit recycling rates in Portsmouth, with its narrow streets of terraced housing.

The electric cargo bike in The Hague which collects plastic waste around the city

Inside of the cargo bike, which will be equipped with a module to label and recognize plastic

PlastiCity is due to finish in February 2023. Interreg 2 Seas 2014–2020 is a European Territorial Cooperation Programme covering England, France, the Netherlands and Belgium (Flanders). The Programme is part-financed by the European Regional Development Fund.