Sidebar navigation

Order laser-cut face shields and download our face shield designs

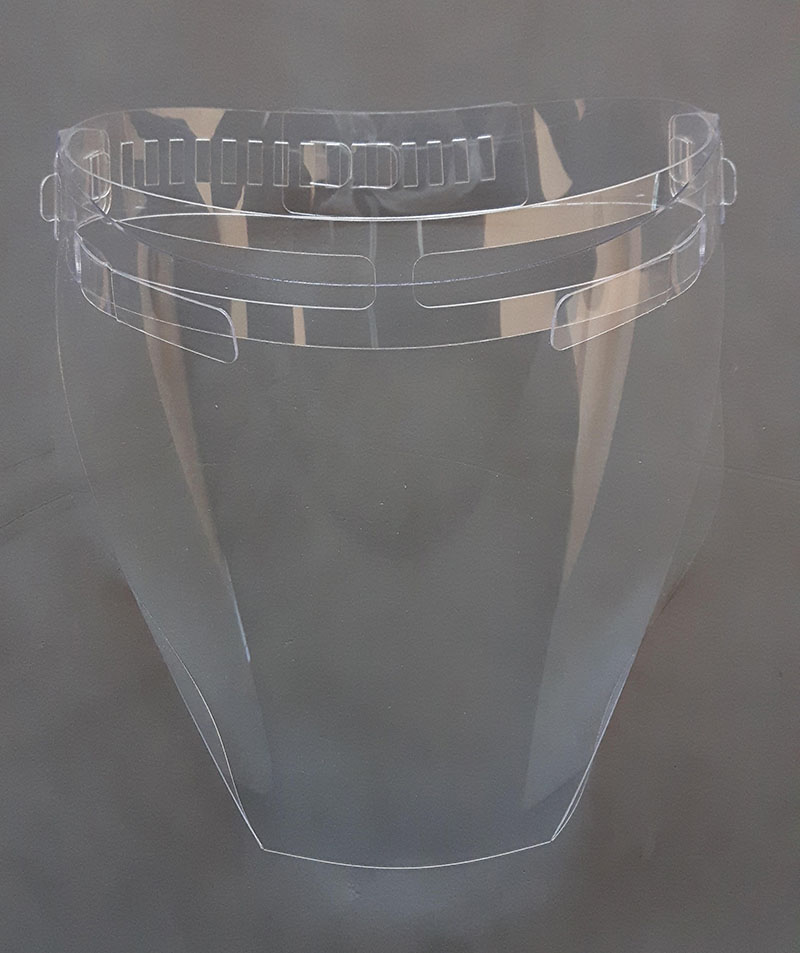

We've manufactured laser-cut face shields and made our face shield designs freely available

We responded to the growing need for personal protection equipment (PPE) during the coronavirus pandemic by manufacturing laser-cut face shields – and by making our face shield designs freely available.

While treating patients and keeping wider society safe, our frontline healthcare staff were exposed to high viral loads of the COVID-19 infection, and had a higher chance of contracting a serious illness related to the virus.

To combat that risk, personal protection equipment (PPE) was used, but it was widely reported that there weren’t enough stocks of PPE to meet demand. To help meet that demand, frontline public services can order shields from us, or download our face shield designs for free.

Order laser cut face shields

Frontline public services can order face shields from us. To place an order, please contact face-shields@port.ac.uk.

Please be aware that supplies may be limited due to the availability of materials and production capacity.

Surgical mask tension release band

Although it's vital for frontline medical staff to wear PPE for longer periods of time, this can quickly become very uncomfortable. This is particularly true when wearing surgical face masks which are secured using elastic fitting around the ears. The elastic can rub on the ears, causing pain and discomfort.

To try and overcome this, the University of Portsmouth is now producing surgical mask tension release bands to help with ear comfort during extended use. We are making these to the opensource specifications.

If you would like to order these for your organisation, or have any other questions, please contact face-shields@port.ac.uk.

Please note that we can only receive orders for these in batches of 100.

Download the face shield designs

We’ve made the designs freely available so other manufacturers, companies and organisations can produce them and maximise availability to healthcare workers.

We have also made files available for any schools and colleges who wish to produce 'approved' PPE equipment using their laser cutting facilities.

Terms and conditions

The work is © John Daltry 2020, who owns the design and all IP in full. It is being shared via the University of Portsmouth website under a Creative Commons Attribution-Non Commercial 4.0 International Public Licence.

Please note the terms and conditions set out in the licence, and in particular note the Licence Conditions set out in Section 3 and the Disclaimer of Warranties set out in Section 5.

Manufacturing to our design

Please note the following when manufacturing the face shields (this information is adapted from the Prusa Research website):

-

Act as if you were infected by the COVID-19 virus. Wear a face mask and a fresh pair of gloves when collecting each batch of printed parts.

-

Store the parts immediately in a sealable bag.

-

Talk with whoever you’re making the shields for and let them know about your manufacturing environment. There is still debate about how long the virus survives on plastic, but most sources say 2–3 days. By letting the packed face shields sit for 2–3 days before distributing them, you’ll greatly reduce risk of transmission. Please do your own research to understand the most up-to-date information on this issue.

-

Do not store the entire stock in one place. Minimise the risk of cross contamination.

How we developed our laser cut face shields

Our highly-skilled and experienced technical and academic team designed the easy-to-produce PPE face shield for healthcare staff and key workers.

The design was iterated based on feedback from our local healthcare partners. Our design consists of the face shield and an adjustable head strap.

The face shields are manufactured easily using laser cutting techniques and are made from a thermoplastic called polyethylene terephthalate (PETG). Please refer to this safety data sheet for PETG.

The shields are Category 1 PPE products and are self-certified CE Marked.

Decontamination: Cleaning your face shield

The following information derives from the Prusa Research website. Please note that the University of Portsmouth is not responsible for the content of external websites and it is recommended that you undertake your own due diligence to ensure the face shields you manufacture or use, are adequately disinfected or sterilized.

Due to COVID-19 being a new enveloped virus, the efficacy of the standard decontamination methods such as those listed below are not fully understood at this stage. However, at present, this knowledge offers the best available approach.

Always use appropriate PPE when handling decontamination fluids, chemicals and equipment and refer to the associated handling advice, warnings and COSHH data sheets of any cleaning products.

Before you apply any disinfection solution, we advise trialling it first near one edge of the visor and inspecting whether the solution has caused damage to the surface of the visor.

Hospitals and other medical workplaces can use their professional sterilizing equipment to decontaminate the face shields. Again we advise sterilizing a single visor using the chosen method followed by a thorough check for possible damage.

Where possible it is highly recommended to submerge (sink) the shield parts into disinfection solutions, this will ensure the solution reaches 100% of the surface. You can also use aerosol (spray), but apply the procedure at least twice to reach as much of the surface as possible. Disinfectant and sporicidal wipes are acceptable, but again ensure that you effectively clean the all surfaces of the face shield.

Most of the solutions will evaporate after several minutes. You can remove the remains using a paper towel. Avoid using the same towel on multiple shields, avoid cross-contamination and always wipe in one direction.

Options for decontamination

| METHOD | CONDITIONS | TIME |

|---|---|---|

|

Clinell Universal wipes |

Wipe all surfaces thoroughly |

> 60 seconds |

|

Clinell Sporicidal wipes |

Wipe all surfaces thoroughly |

> 60 seconds |

|

Soapy water |

Repeated washing |

5+ minutes |

|

Autoclave (cold) |

56-60°C |

60 minutes |

|

Isopropyl alcohol |

Wipe or immerse |

5+ minutes |

|

Ethanol (>70%) |

Wipe or immerse |

5+ minutes |

|

Descogen®-S (1.5%) |

Wipe or immerse |

30 minutes |

|

Sodium Hypochlorite (Savo) |

Wipe or immerse |

5+ minutes |

|

IPA steam |

45-65°C (patent info) |

30-90 minutes |

|

Hydrogen Peroxide (6-25%) |

Follow local procedures |

Follow local procedures |

|

Ozone |

Follow local procedures |

Follow local procedures |

|

Gamma radiation |

Follow local procedures |

Follow local procedures |

|

UV-C |

Follow local procedures |

Follow local procedures |

*Based on this study, the SARS-CoV is relatively resistant to UV irradiation.

Methods which are NOT recommended

The methods listed below were tested and evaluated as not ideal for the decontamination process, either due to structural damage to the shield or other reasons as specified.

| METHOD | CONDITIONS | CONCLUSION |

|---|---|---|

|

Autoclave (hot) |

High temperature 120°C, and pressure 200 kPa |

PETG material limit, high temperature will deform shield |

|

Ethylene oxide |

Ethylene oxide, low temperature (25-55°C) |

Effective sterilisation, but time-consuming process |

Please refer to the GOV.UK website for additional advice

Disposing of the face shield

If cracking occurs or the optical clarity of your shield is compromised, please dispose of it.

The white and transparent film foils are non-recyclable, so please dispose in non-recycled plastic waste.

The shield and headband are composed of PETG, which is not commonly recycled and can act as a contaminant in PET recycling. Please keep separate from other plastics recycling, and contact your recycling provider to check if they provide a PETG recycling service.